Commercial Services…

We serve throughout Northern Illinois!

Whether your needs are for new construction, re-roof, roof replacement or roof repairs, you can count on Local Roofing Co., Inc. for competitive pricing, quality materials, professional craftsmanship and unmatched warranties. Don’t take a chance.

Hire the Professionals at Local Roofing Co., Inc.!

We serve the Entire Northern Illinois and Surrounding Areas.

| Insurance Coverage | Local Roofing Coverage |

|---|---|

| Property Damage | $2,000,000 |

| Personal Injury | $1,000,000 |

| General | $2,000,000 |

| Products | $2,000,000 |

| Work Comp. | $500,000 |

| Auto Liability | $1,000,000 |

| Umbrella | $10,000,000 |

Safety…

Local Roofing Co., Inc. has a professional ongoing Safety Program in place for all its employees. We are consistently updating our safety training of our employees including OSHA 10 hour certification of our foremen. This is reflected in our excellent workers compensation, experience rating. Before a roofing project starts, we will meet with the owners representative to conduct a pre-job meeting. In this meeting we will discuss scheduling, OSHA safety requirements and job-site set-up.

- Job site audits conducted by: Eddie Techaria, our in house Full Time Safety Coordinator.

- Copies of safety program and audits available upon request.

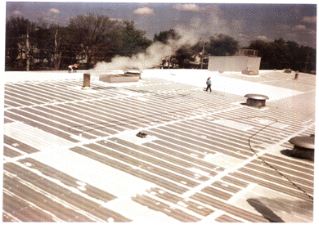

Thermoplastic roof membranes are materials whose chemical and physical property characteristics allow them to repeatedly soften when heated, and harden when cooled. Because of this chemical nature, thermoplastic membrane sheets are seamed with hot air welding. Two common categories of thermoplastic membrane are Thermoplastic Olefin (TPO) and Polyvinyl Chloride (PVC). The membrane is usually produced as a reinforced, white sheet ranging in thickness from 45 to 80 mils. (thousandths of an inch). Optional colors can be selected and warranties can be offered up to 20 years.

Installation of thermoplastic membrane commercial roof systems are commonly either fully-adhered, rock ballasted or mechanically attached.

Advantages of TPO or PVC roofing are:

- Energy efficient reflective surface

- Seam strength of 3 to 4 times that of other single-ply systems

- High chemical resistance

- Low installation cost

- Lack of odor or fumes during installation

- Low maintenance

- Easy to repair

Advantages of Single-Ply EPDM Roofs are:

- Cyclical membrane fatigue resistance

- Proven hail resistance

- High resistance to ozone

- Weathering and abrasion

- Flexibility in low temperatures

- Lack of odor or fumes during installation

- Low maintenance and easy to repair

-

Annually, EPDM accounts for over 1 billion square feet

of new commercial roof coverings in the United States

and is the most frequently used roofing material in the

commercial roofing marketplace.

Advantages of built-up roofing are:

- Long life expectancy

- Tough, durable roof

- High resistance to roof top traffic

- Puncture Resistant

Advantages of modified bitumen roofing are:

- Proven history

- Tough, durable roof

- High resistance to roof top traffic

- High puncture and tear resistant

- Variety of application

- Easily maintained

Advantages of Built-Up Roof Restoration with Polyester membrane are:

- A life expectancy of 12-17 years

- Easy to apply, no heating or open flames

- The polyester membrane will not rot

- Avoids the high cost of total roof replacement

Advantages of Metal Roof Restoration are:

- Inexpensive cost of extending your roof with up to a 10+ year warranty.

- Reflectivity and Energy Star ratings.

- Non-invasive or penetrating roof system and quick application.

- Easy to apply, no heating or open flames